Frustrated by chillers that STRUGGLE to keep up?

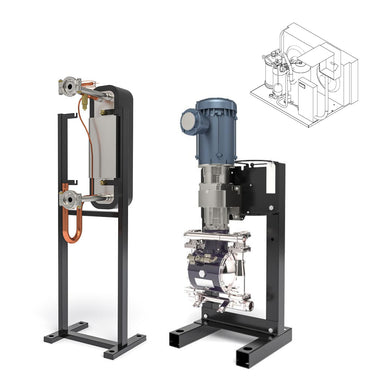

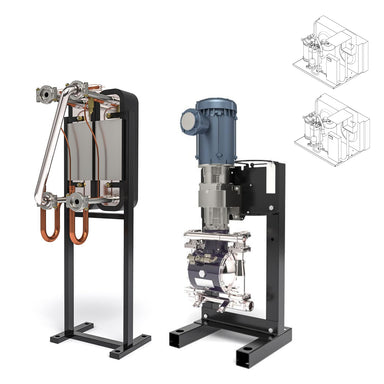

This chiller system is ideal for recovering and condensing hydrocarbons or alcohols in large extraction systems. Unlike traditional chillers, which use refrigerant to

chill a thermal transfer fluid that is then piped to the application, this chiller can be configured to chill the heat exchangers on the system with refrigerant directly. This eliminates the need for thermal transfer fluids used by other chillers for greater overall efficiency. The design is low maintenance, and easy to operate once installed - just flip the switch and watch it get cold!

FEATURES & BENEFITS

- Condenses up to 75lbs of butane p/hr.

- Single stage cooling

- On-roof Refrigerant

- Keeps the heat outside

- Fully C1D1 certified compliant

NEED MORE CHILLING POWER? Two compressor units are available, and can get you colder, FASTER!

| Models | Motor | Pump | CO2 |

|---|---|---|---|

| -40-1PH | 2 HP 1 Phase |

Yes | No |

| -40-3PH -40ATEX |

2 HP 3 Phase |

Yes | No |

| Technical Data | |

|---|---|

| Power | 208-230 VAC 3-Phase |

| Max Design Pressure | Low side 180 PSIG High Side 500 PSIG |

| Current Draw | 23 amps 1-Phase 14 amps 3-Phase |

| Minimum Circuit Ampacity | 32.7 amps 3-Phase |

| Maximum Fuse / Breaker | 50 amps 3-Phase |

| Refrigerant Type | R 134A - R 22 - R 404A R 407A - R 407°C - R 407°F |

| Temperature Range | -45° - 20°C |

| Dimensions | 10” W x 25.5”H x 33”L |

| Weight | 75lb |

| Power Cord | Hard-Wired |